|

|

|

The Mystery of " Tuned Pipes"

4 Part Series

How to Determine Length

PART 2

Introduction:

The " tuned pipe" or properly called Expansion Chamber has long been the subject of considerable mystery. After long and intense study, with verification on the Inertial Dynamometer, I believe I can simplify its application to our RC Hobby! This device is not a "Black Box" which can not be solved with mathematics, chemistry and physics. The definitive study completed by a research team at The Queens University of Belfast and presented in their Design and Simulation of Two-Stroke Engines gives imperial data upon which to solve this mystery. I have applied the mathematics and physics, as well as the chemistry of our fuel concoction, to their formulations and am able to solve these mysteries. I will present this in 4 parts to be discussed in detail. Part 1 addresses the effect of Exhaust Timing on the pipe length. Part 2 addresses the effect of Temperature on the Pipe Length. Part 3 addresses the effect of Compression Ratio on pipe length. Part 4 deals with the RPM at which you make Maximum HP. At the end of EACH of the 4 parts, I will provide BASIC STATEMENTS TO ALLOW YOU TO MAKE CHANGES IN LENGTH BASED ON SPECIFIC CRITERIA. If this seems to be much too technical, just look at the conclusions at the end of each of the 4 parts!

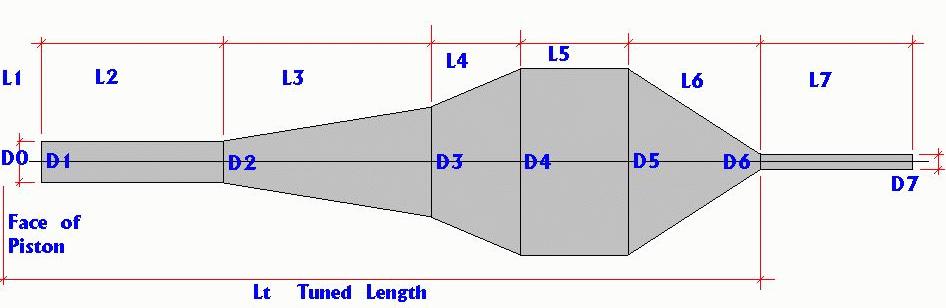

Length Defined: The tuned length of an expansion chamber MUST be accurately measured from the FACE OF THE PISTON to the START OF THE STINGER.

TEMPERATURE EFFECT ON PIPE LENGTH:

The temperature of the gases inside the pipe is the PRIMARY CONTRIBUTOR to a determination of the correct pipe length. For each 10 degrees of temperature increase in pipe gases the following lengthening of the pipe must occur. 21 - .044", 45 - .050", 67 - .052", 90 - .059".

An Example: In my 21 Nova Rossi, I increased the compression ratio by 1 point and the gas temperature inside the pipe dropped by 50 degrees, because the mixture had to be much richer. Using the above information, I had to shorten the pipe because my gas temperature decreased 50 degrees. That is 5 X .044" or .220" (almost a quarter of an inch)!!

How do you measure the temperature of the gases in your pipe? Until now that has been very difficult, but after finding a tool in the MSC (Manhattan Supply Company Catalog), it is now VERY EASY. They have a product, which is like a crayon (Tempil) which you buy in various temperatures. You make several small marks (1 for each different temperature) on the outside of the pipe and after a HARD run, bring the boat in and look to see which marks have melted. The highest mark that melted tells you what the operating temperature is. Since you made the mark on the outside of the pipe, it is probably a little low. I would suggest that you make the mark near the start of the pipe (the hottest area) to be closer to the inside temperature. The Product is called Tempil Temperature Indicators and can be ordered from MSC at 1-800-645-7270. Get their catalog; it has EVERYTHING in the world! The price for these crayons is currently $7.80 each and they come in 50-degree increments. How do you think the rise of nitro affects the temperature of the gases in the pipe? This is a test, which has not been completed on our Inertial Dyno, but will in the next month or so. It is obvious that a rise in nitro should increase the inside gas temperature. If you change to higher nitro percentage, be prepared to lengthen the pipe. I will advise all registered owners of "The Engine Analysis Software " of these findings!

In conclusion for every 10 degree rise in pipe gas temperature, you will have to lengthen your pipe as follows: 21 - .044", 45 - .050", 67 - .052", 90 - .059". All the information presented here can be learned by using "The Pipe Design Program" from MWD & Associates.

NEXT MONTH:

The effect of Compression Ratio on Pipe Length

.

|

ENGINE Analysis Software for the Serious RC Competitor

|