The Engine Analysis Program

Part 3

"The Rotor or Crank Induction Assembly"

The rotor or crank induction assembly is the

heart of the engines low end power! How is this so? Consider

that the engine is "A PUMP". The efficiency

the engine shows in this role as a pump is dependent upon

a GREAT seal of the rotor disk to the backplate or the crank to

the front end. When your engine comes to you from the factory,

it has adequate clearance between the crank and the front housing

or the rotor disk and the backplate (For the sake of this tech

note I will use the crank induction and the crank fit to the front

housing in a parallel with the rotor and its fit with the back plate,

that way I won't have to repeat this every time I use an illustration

for one or the other). If you were manufacturing an engine, you

would make the interchangeability of parts easy and the fit within

a range to accommodate the widest range of machining tolerances.

We can make the fit better with the rotor assembly! The flatness

of the rotor disk and the back plate assembly can be made

MUCH better. How can you do this? By lapping the back plate assembly

on a VERY flat surface. I use a ground plate available from MSC

for about $25. Some people say they use a piece of glass (it

is really not very flat and I wouldn't suggest that you use glass).

I then apply a small amount of "Non-Imbedding Garnet"

or special aluminum lapping compound available from the Helical

Lap Company. If you want to buy a very small amount of the lapping

compound, I would suggest that you buy it from John Ackerman at

jfacustom@earthlink.net. This is the same compound that I use and it works

VERY well and does not imbed in aluminum. Be VERY careful that

you don't use diamond or some other compound that will imbed in

the aluminum, as you will continue to get lapping of all the internal

components of your engine. How then do you lap the back plate

assembly? Applying a small amount of the lapping compound on

the ground plate you pull the back plate assembly toward you in

a continuous stroke. Rotate the assembly 90 degrees and move

it forward, rotate another 90 degrees and move it toward you,

etc. This will prevent lapping in one area only, and you will

get a perfectly smooth and FLAT back plate assembly. How about

the rotor disk? If you have access to a lathe, you will want

to use a piece of bronze and face the surface flat and drill a

hole the same size as the flange on the rotor disk. Apply a small

amount of the lapping compound and start lapping, holding firm

pressure against the disk. If you don't have the capability

to lap the disk, lap only the back plate! If you lap the back plate

only it will be 100% better than it came.

Wash up the components using soap and water with

a toothbrush, being sure to get ALL the lapping compound removed.

You are now ready to fit the back plate and rotor

disk. Using a .0015 to .002 feeler gauge, place it between the

disk and back plate on ONE SIDE ONLY. Secure the rotor pin and

Loctite using #242 blue Loctite. This will give you about .0005

+/- clearance. Spin the disk and make sure it spins freely with

no evident high spots. The assembly is now ready to put back onto

the engine. Check the fit and re-lap at least 3 or 4 times per

season and you will be VERY pleased with the launchability and

power of your engine. This is the reason, when your boat stops launching

easily. The rotor fit has gone away and it needs to be re-lapped.

What about the crank induction engine. Sorry, you can't re-lap

it, you must get a new case and crank assembly. To keep the fit

perfect in the front induction (crank) engine CHANGE THE BEARINGS

BEFORE THEY FAIL!!!!!! I change my bearings during the Winter

and once before the Nationals as preventive maintenance. I have

been using a 3.5 Nova Rossi for 4 seasons and it keeps getting

better and better with no loss of seal between the crank and housing

(CHANGE YOUR BEARINGS REGULARLY!!!)

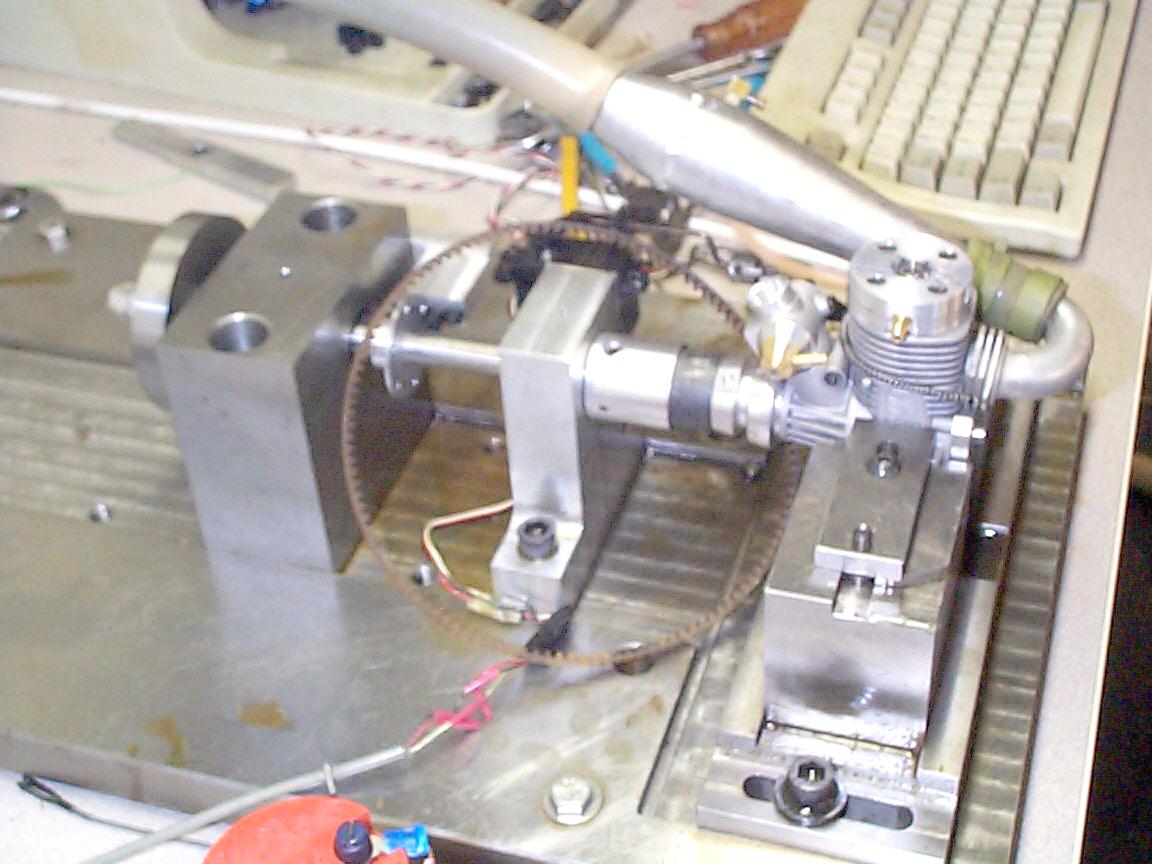

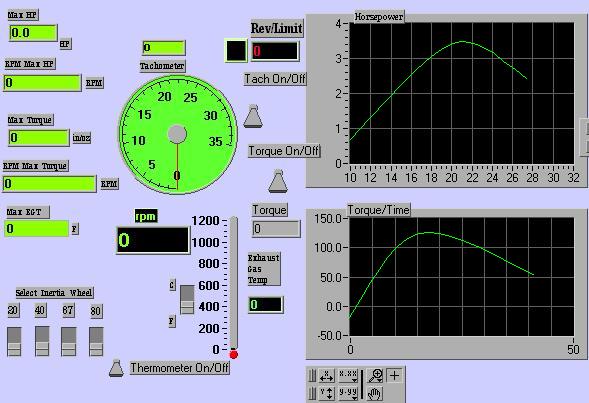

For those of you who like to have an expert do your engine work, I suggest that you send an E-Mail message

to John Ackerman owner of JFA Custom. He is the best engine builder around and has

all the tools to make the job easy for him. By the way, John and I along with Norris Sparks,

Brian Callahan and Joe Kramer, are building an inertial dyno from the SAE paper

written by Dr. Kee. Here is a picture of it and a picture of the virtual instrumentation

we use to generate charts and all the readouts.

Until NEXT MONTH............... Rotor Timing.....

|